In the manufacturing industry, making informed decisions is crucial for maintaining efficiency, reducing costs, and staying competitive. With the vast amount of data generated throughout the production process, supply chain, and customer interactions, the potential for data-driven decision-making is immense. However, to fully capitalize on this potential, manufacturers must develop robust strategies for collecting, analyzing, and utilizing data effectively. This is where data engineering and advanced analytics come into play.

The Importance of Informed Decision-Making in Manufacturing

Manufacturing is a complex, multifaceted industry that requires precise coordination of various elements, including production schedules, inventory management, quality control, and customer fulfillment. Making decisions based on outdated or incomplete information can lead to costly mistakes, such as overproduction, underutilization of resources, or poor-quality products. In contrast, informed decision-making, powered by accurate and timely data, enables manufacturers to optimize their operations, anticipate challenges, and capitalize on opportunities.

Key Data Sources for Decision-Making

Production Data:

Production data includes information from every stage of the manufacturing process, from raw material input to final product output. This data is critical for understanding production efficiency, identifying bottlenecks, and ensuring that products meet quality standards. By analyzing production data, manufacturers can make informed decisions about process improvements, equipment maintenance, and resource allocation.

Supply Chain Data:

The supply chain is the lifeline of manufacturing, and its efficiency directly impacts a company’s ability to meet customer demands. Supply chain data includes information on supplier performance, inventory levels, transportation logistics, and demand forecasts. Utilizing this data allows manufacturers to optimize their supply chain operations, reduce lead times, and minimize the risk of disruptions.

Customer Data:

Customer data provides insights into buying behaviors, preferences, and feedback. This data is invaluable for making informed decisions about product development, customization, and marketing strategies. By understanding customer needs and trends, manufacturers can tailor their offerings to meet market demands and enhance customer satisfaction.

Financial Data:

Financial data, such as cost structures, profit margins, and sales figures, is essential for making informed business decisions. This data helps manufacturers evaluate the financial impact of operational changes, assess the profitability of different product lines, and plan for future investments. Financial data also plays a critical role in budgeting, forecasting, and financial risk management.

Environmental and Compliance Data:

With increasing regulatory requirements and a growing emphasis on sustainability, manufacturers must also consider environmental and compliance data. This includes information on energy consumption, emissions, waste generation, and adherence to industry standards. Utilizing this data enables manufacturers to ensure compliance, reduce environmental impact, and support sustainability initiatives.

Techniques for Utilizing Data in Decision-Making

Data Integration and Centralization:

To make informed decisions, manufacturers need a comprehensive view of their operations. Data integration and centralization are crucial techniques for bringing together data from various sources into a single platform. This enables manufacturers to analyze data holistically, identify correlations, and make decisions based on a complete understanding of the factors at play.

Real-Time Data Analysis:

The ability to analyze data in real-time is a game-changer for decision-making in manufacturing. Real-time data analysis allows manufacturers to monitor production processes, equipment status, and supply chain operations as they happen. This immediacy enables quick decision-making, helping to prevent issues before they escalate and ensuring that operations run smoothly.

Predictive Analytics:

Predictive analytics involves using historical data to forecast future trends and outcomes. In manufacturing, predictive analytics can be applied to various aspects, such as predicting equipment failures, anticipating demand fluctuations, or optimizing inventory levels. By leveraging predictive models, manufacturers can make proactive decisions that minimize risks and maximize efficiency.

Machine Learning and AI:

Machine learning and artificial intelligence (AI) are advanced technologies that can significantly enhance data-driven decision-making. These technologies can analyze large volumes of data, identify patterns, and make recommendations based on complex algorithms. For example, AI-driven systems can suggest process improvements, optimize production schedules, or recommend maintenance actions, all of which contribute to more informed decision-making.

Data Visualization and Reporting:

Data visualization and reporting tools are essential for translating complex data into actionable insights. By presenting data in visual formats, such as charts, graphs, and dashboards, manufacturers can easily understand trends, patterns, and key metrics. These tools enable decision-makers to quickly grasp the implications of data and make informed choices.

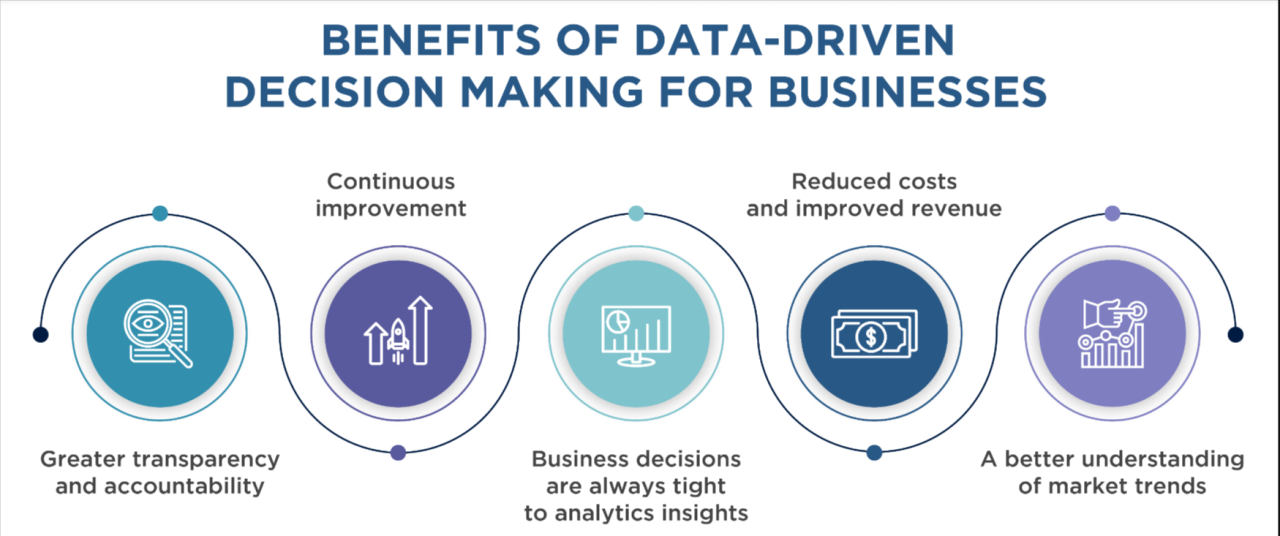

The Strategic Value of Data-Driven Decision-Making

In an increasingly competitive manufacturing landscape, the ability to make informed decisions based on accurate and timely data is a significant strategic advantage. Data-driven decision-making not only enhances operational efficiency but also supports long-term business goals, such as innovation, customer satisfaction, and sustainability.

By leveraging data engineering techniques and advanced analytics, manufacturers can ensure that their decisions are grounded in reality, reducing the risk of costly errors and improving overall business performance. As the industry continues to evolve, those who prioritize data-driven decision-making will be better positioned to navigate challenges and seize opportunities.

Utilizing data for informed decision-making is a powerful approach that can transform manufacturing operations. By integrating and analyzing data from production, supply chain, customer interactions, and financial performance, manufacturers can make decisions that enhance efficiency, reduce costs, and drive growth. With the right data engineering techniques and analytical tools, companies can unlock the full potential of their data and achieve sustained success in an increasingly data-driven world.