- Alex M

- Supply Chain

- 0 Comments

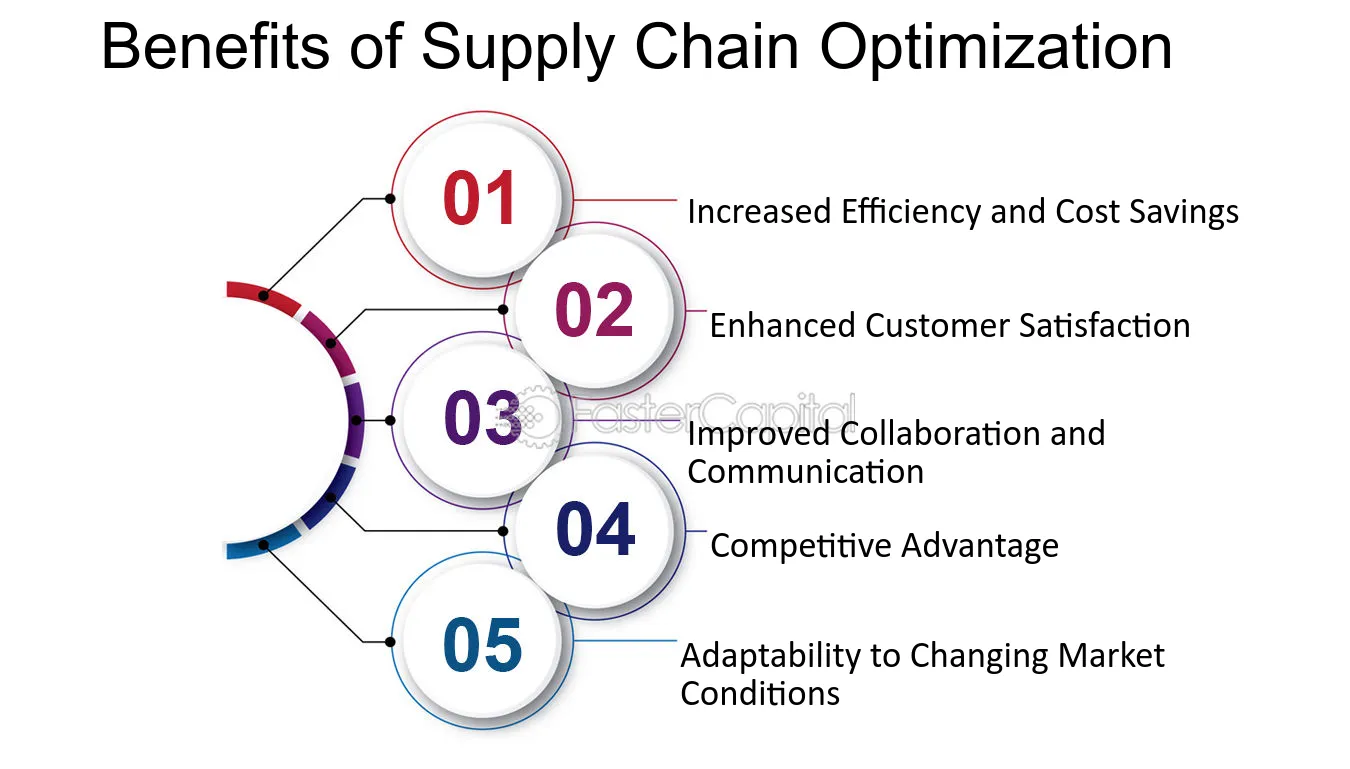

Supply chain optimization is a strategic approach that aims to enhance the efficiency and effectiveness of supply chain processes. By optimizing supply chain operations, businesses can achieve significant improvements in logistics, inventory management, and overall cost savings. This comprehensive guide explores the various benefits of supply chain optimization, with detailed explanations of key areas such as enhanced logistics and transportation efficiency, improved inventory management, and cost optimization.

1. Enhanced Logistics and Transportation Efficiency

Logistics and transportation are critical components of the supply chain. Efficient logistics ensure that goods are moved from suppliers to customers in the most efficient and cost-effective manner. Transportation efficiency, on the other hand, focuses on optimizing the movement of goods to reduce transit times and costs

Benefits:

- Reduced Transportation Costs: By optimizing routes and consolidating shipments, businesses can significantly reduce transportation expenses

- Faster Delivery Times: Efficient logistics enable quicker delivery of goods, enhancing customer satisfaction.

- Improved Carrier Relationships: Optimized logistics lead to better collaboration with carriers, resulting in more favorable terms and reliable service.

Implementation Tips:

- Utilize transportation management systems (TMS) to plan and optimize routes.

- Implement real-time tracking and monitoring to improve visibility.

- Collaborate with multiple carriers to find the most cost-effective and reliable options

2. Improved Inventory Management Through Optimization

Inventory management involves maintaining the right balance of stock to meet customer demand while minimizing holding costs. Optimization techniques such as Just-in-Time (JIT) and ABC analysis can help achieve this balance.

Benefits:

- Reduced Holding Costs: By minimizing excess inventory, businesses can reduce storage and handling costs.

- Decreased Stockouts: Optimized inventory management ensures that products are available when needed, reducing the risk of stockouts.

- Better Demand Forecasting: Accurate demand forecasting helps in maintaining optimal inventory levels, improving service levels.

Implementation Tips:

- Use inventory management software for real-time tracking and analysis

- Implement JIT inventory systems to align inventory levels with demand.

- Conduct regular inventory audits and categorize inventory using ABC analysis.

3. Cost Optimization and Savings in the Supply Chain Process

Cost optimization involves identifying and eliminating unnecessary costs within the supply chain. This can be achieved through process improvements, strategic sourcing, and leveraging economies of scale

Benefits:

- Lower Operational Costs: Streamlined processes and efficient resource utilization lead to cost savings

- Improved Profit Margins: Reduced supply chain costs translate to higher profit margins.

- Competitive Advantage: Cost-efficient supply chains enable businesses to offer competitive pricing.

Implementation Tips:

- Conduct regular cost analysis to identify areas for improvement.

- Implement process improvement methodologies such as Lean and Six Sigma.

- Negotiate better terms with suppliers and explore bulk purchasing options.

4. Enhanced Customer Satisfaction

Optimized supply chains ensure that products are delivered to customers on time and in perfect condition. This enhances customer satisfaction and loyalty.

Benefits:

- On-Time Delivery: Efficient supply chains reduce lead times, ensuring timely delivery of products.

- Product Quality: Effective supply chain management ensures that products are handled properly, maintaining quality.

- Improved Customer Experience: Reliable and efficient supply chains enhance the overall customer experience.

Implementation Tips:

- Use customer feedback to identify areas for improvement in the supply chain

- Implement quality control measures at every stage of the supply chain.

- Ensure clear communication and transparency with customers regarding delivery times.

5. Increased Flexibility and Responsiveness

An optimized supply chain can quickly adapt to changes in demand, market conditions, and disruptions. This flexibility is crucial in today’s dynamic business environment.

Benefits:

- Adaptability to Market Changes: Flexible supply chains can quickly respond to shifts in market demand and supply.

- Resilience to Disruptions: Optimized supply chains are better equipped to handle disruptions such as natural disasters or supply shortages.

- Enhanced Agility: Businesses can quickly scale operations up or down based on demand

Implementation Tips:

- Develop contingency plans for potential supply chain disruptions

- Use real-time data to monitor and respond to changes in demand.

- Implement agile supply chain practices to enhance responsiveness.

6. Better Collaboration and Communication

Effective supply chain optimization fosters better collaboration and communication among all stakeholders, including suppliers, manufacturers, and customers.

Benefits:

- Improved Coordination: Enhanced communication leads to better coordination and synchronization of supply chain activities.

- Stronger Supplier Relationships: Collaborative relationships with suppliers result in better terms and more reliable service.

- Increased Transparency: Clear communication ensures that all stakeholders are informed and aligned, reducing misunderstandings and errors.

Implementation Tips:

- Use collaboration tools and platforms to facilitate communication

- Establish regular meetings and updates with supply chain partners

- Foster a culture of transparency and open communication.

7. Enhanced Supply Chain Visibility

Visibility refers to the ability to track and monitor supply chain activities in real-time. Enhanced visibility allows businesses to identify and address issues promptly.

Benefits:

- Proactive Issue Resolution: Real-time monitoring enables quick identification and resolution of supply chain issues.

- Improved Decision-Making: Access to real-time data enhances decision-making capabilities

- Better Inventory Management: Visibility into inventory levels across the supply chain ensures optimal stock levels.

Implementation Tips:

- Implement supply chain visibility tools and software.

- Use IoT devices and sensors for real-time tracking.

- Share data and insights with all stakeholders to enhance visibility.

8. Sustainable Supply Chain Practices

Sustainability in supply chain management involves adopting practices that reduce environmental impact and promote social responsibility.

Benefits:

- Reduced Carbon Footprint: Sustainable practices reduce greenhouse gas emissions and environmental impact

- Enhanced Brand Reputation: Commitment to sustainability improves brand image and customer perception

- Long-Term Cost Savings: Efficient use of resources leads to long-term cost savings.

Implementation Tips:

- Conduct sustainability audits to identify areas for improvement.

- Implement green logistics practices such as eco-friendly transportation

- Partner with suppliers who follow sustainable practices.

9. Improved Risk Management

Supply chain optimization includes identifying and mitigating risks to ensure a smooth and reliable supply chain operation.

Benefits:

- Reduced Supply Chain Disruptions: Proactive risk management minimizes the impact of disruptions.

- Enhanced Resilience: Optimized supply chains are better equipped to handle unexpected events

- Better Compliance: Effective risk management ensures compliance with regulations and standards.

Implementation Tips:

- Conduct regular risk assessments to identify potential threats.

- Develop contingency plans for various risk scenarios.

- Use risk management tools and software to monitor and mitigate risks.

10. Data-Driven Decision Making

Data-driven decision making involves using data analytics to inform supply chain strategies and decisions. This approach ensures that decisions are based on accurate and relevant data.

Benefits:

- Informed Decisions: Data-driven insights lead to more accurate and effective decisions.

- Enhanced Performance: Data analytics helps identify areas for improvement and measure performance.

- Competitive Advantage: Businesses that leverage data analytics gain a competitive edge in the market

Implementation Tips:

- Invest in data analytics tools and software.

- Train employees on how to interpret and use data insights.

- Regularly review and analyze supply chain data to inform decisions.

Supply chain optimization offers numerous benefits, including enhanced logistics and transportation efficiency, improved inventory management, cost optimization, and more. By implementing these best practices, businesses can achieve a more efficient, resilient, and competitive supply chain. Embrace advanced analytics, foster collaboration, and leverage technology to unlock the full potential of your supply chain.