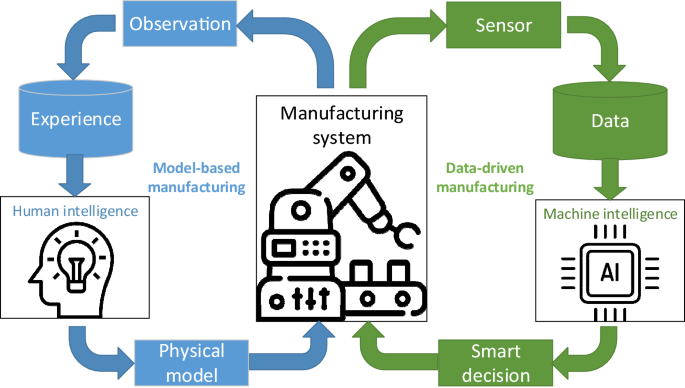

In the era of Industry 4.0, manufacturing is undergoing a profound transformation driven by advanced technologies and data-driven decision-making. At the heart of this revolution is data engineering, a discipline that ensures the efficient collection, processing, and utilization of data. Data engineering expertise brings numerous benefits to the manufacturing industry, enhancing productivity, optimizing processes, and driving innovation. This article explores the key benefits of data engineering expertise in manufacturing.

Introduction to Data Engineering in Manufacturing

Data engineering involves designing, building, and maintaining the infrastructure and systems that allow for the effective collection, storage, and analysis of data. In manufacturing, data engineers work with large volumes of data generated by machines, sensors, and production systems to create data pipelines that transform raw data into actionable insights. This expertise is crucial for leveraging advanced analytics, machine learning, and real-time monitoring to optimize manufacturing processes.

Benefits of Data Engineering Expertise

Enhanced Operational Efficiency

One of the primary benefits of data engineering in manufacturing is enhanced operational efficiency. By creating robust data pipelines, data engineers ensure that data flows seamlessly from various sources to analytics platforms. This real-time data availability enables manufacturers to monitor production processes closely, identify bottlenecks, and implement improvements promptly.

Example: A car manufacturer uses data engineering to integrate data from assembly lines, quality control sensors, and inventory systems. This integration allows for real-time monitoring of production stages, enabling quick adjustments to improve efficiency and reduce downtime.

Improved Product Quality

Data engineering expertise helps in maintaining and improving product quality by enabling continuous monitoring and analysis of production data. With accurate and timely data, manufacturers can detect defects early in the production process and take corrective actions before the defects escalate.

Example: In the electronics manufacturing industry, data engineers create pipelines that collect data from quality control inspections at various production stages. Analyzing this data in real-time allows for immediate identification of defects, leading to higher-quality products and reduced waste.

Predictive Maintenance

Predictive maintenance is a game-changer for the manufacturing industry, reducing unplanned downtime and extending the lifespan of equipment. Data engineering plays a crucial role in predictive maintenance by processing and analyzing data from machine sensors to predict when maintenance is needed.

Example: A steel manufacturing plant uses data engineering to collect and analyze data from sensors embedded in machinery. Predictive models use this data to forecast potential equipment failures, allowing maintenance teams to perform timely interventions, thus preventing costly breakdowns.

Optimized Supply Chain Management

Effective supply chain management is vital for manufacturing success, and data engineering expertise enables manufacturers to optimize their supply chains. By integrating data from suppliers, production lines, and distribution networks, data engineers create a comprehensive view of the supply chain, facilitating better decision-making.

Example: A consumer goods manufacturer integrates data from suppliers, inventory systems, and sales channels. This integration allows for real-time tracking of raw materials, production status, and product distribution, enabling the manufacturer to optimize inventory levels and reduce lead times.

Enhanced Decision-Making

Data engineering provides the foundation for advanced analytics and business intelligence, empowering manufacturers to make data-driven decisions. By ensuring that data is accurate, timely, and accessible, data engineers enable managers and decision-makers to gain deeper insights into their operations.

Example: A pharmaceutical company employs data engineering to consolidate data from research and development, production, and sales departments. This consolidation provides comprehensive insights that inform strategic decisions, such as optimizing production schedules and aligning product development with market demand.

Innovation and Competitive Advantage

Data engineering expertise fosters innovation by enabling manufacturers to experiment with new technologies and approaches. By leveraging big data and advanced analytics, manufacturers can identify trends, develop new products, and improve existing processes, gaining a competitive edge in the market.

Example: An automotive parts manufacturer uses data engineering to analyze market trends and consumer preferences. This analysis helps the company develop innovative products that meet emerging customer needs, giving it a competitive advantage.

Scalability and Flexibility

Data engineering provides the scalability and flexibility needed to handle growing data volumes and evolving business requirements. Scalable data architectures and pipelines ensure that manufacturers can efficiently process and analyze increasing amounts of data without compromising performance.

Example: A global manufacturing company implements a scalable data lake architecture to manage data from multiple production facilities worldwide. This architecture allows the company to scale its data processing capabilities as its operations expand, ensuring consistent performance and data availability.

Implementing Data Engineering in Manufacturing

Building a Skilled Team

Successful implementation of data engineering in manufacturing requires a team of skilled data engineers who understand both data science and manufacturing processes. These professionals design and maintain the data infrastructure, ensuring it meets the specific needs of the manufacturing environment.

Investing in the Right Tools

Investing in the right tools and technologies is crucial for effective data engineering. Manufacturers should consider advanced data processing platforms, cloud services, and real-time analytics tools that support scalable and efficient data pipelines.

Emphasizing Data Quality

Ensuring high data quality is essential for reliable analysis and decision-making. Implementing robust data quality management practices, including data profiling, cleansing, and validation, helps maintain the accuracy and integrity of data.

Continuous Monitoring and Improvement

Data engineering is an ongoing process that requires continuous monitoring and improvement. Regularly reviewing data pipelines, updating systems, and incorporating feedback from users help ensure that the data infrastructure remains efficient and effective.

Data engineering expertise is a critical asset for the manufacturing industry, offering numerous benefits that enhance operational efficiency, product quality, and decision-making. By leveraging advanced data engineering techniques, manufacturers can optimize their processes, reduce costs, and drive innovation. As the manufacturing landscape continues to evolve, investing in data engineering capabilities will be essential for maintaining a competitive edge and achieving long-term success.